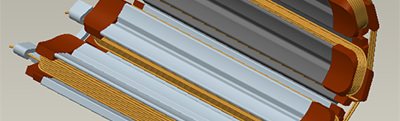

Assemblies and processes for electric motors

Our development team uses 50 years of experience in applying the technical possibilities of plastic, copper and iron to conduct research in the future-oriented field of electric drives and to consolidate another focus in schlaeger's product portfolio. The result are assemblies and components with the same characteristics as our other parts: extremely robust against vibration, thermo-mechanical effects and media and at the same time convincing by high functional integration, efficient field generation and costs.

This is matched by the strategic investment in our manufacturing capacities: in 2018, schlaeger opened a new electric motor microfactory (EMF), where assemblies for electric drives are created in up to six manufacturing steps. Conversion to other variants through appropriate tooling and programming is both simple and fast. Our challenges range from highly integrated metal-plastic components to pre-assembled stators - the individual requirements of our customers determine the path we take. In the process, our customers can rely on worldwide delivery in series quality - from samples to quantities in the millions.

Special features:

- Development of components for pump stator housings - from pole chains interconnected over d=9 mm to robust and efficient stator segments for gear-integrated electric machines

- efficient field generation and high functional integration for single poles/stators

- development and production of molds for primary forming processes and assembly.